Microfluidics and LOC

Microfluidics and LOC

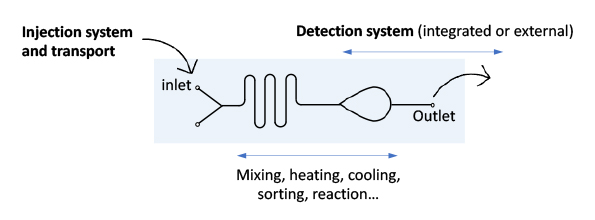

Lab on Chip (LOC) are miniaturized microfluidics devices able to execute complex laboratory protocols. LOCs integrate multiple laboratory functions on few square centimeters handling extremely small fluid volumes (μl to pl)

The advantages of miniaturization are:

- Minimal reagent consumption

- Low reaction volumes

- High surface-to-volume ratio (Reduction in reaction time, high heat and mass transfer, that means fast heating, cooling and diffusion)

- High yields, reproducibility and robustness

- Good handling of droplets

Due to their features, LOC are one of the cutting-edge technologies in different applications

POINT OF CARE

Diagnostics

High-throughput screening

Drug screening

Forensics

Environmental monitoring

Agrifood and water monitoring

ADVANCED MEDICINE

Personalized medicine

Multi-omics research

Tissue engineering

Organ on chip

Cancer diagnosis

Patient monitoring

RESEARCH

Generation of μ/n particles

Drugs delivery

Biosensors

Microarray

Cell sorting

Cellular culture

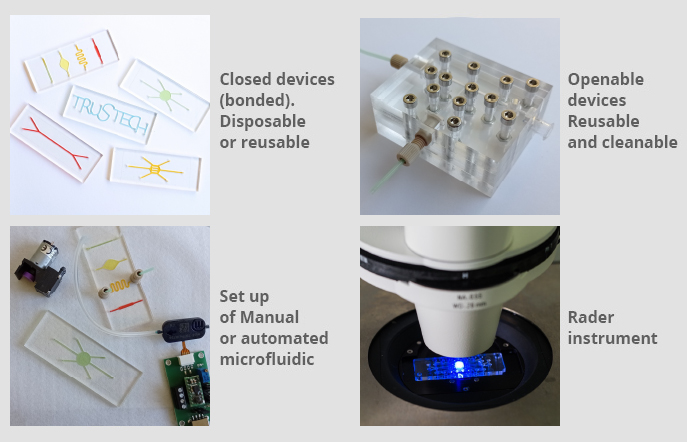

We design and realize customized microfluidic device for research and industrial applications

Our service includes different levels of development: from feasibility to industrialization.

We are able to prototype LOCs with different technique and provide integrated microfluidic and detection system for benchtop or portable application.

OUR SUPPORT

DESIGN

Definition of requirements, constraints, geometries and interfaces

3D CAD model

PROTOTYPE AND SMALL APPLICATIONS

Disposable LOC

Reusable LOC

Microfluidic circuit

Reader instrument

FUNCTIONALITY CHECK

Chip sealing, interfaces, valves or other elements

Bio-testing

INDUSTRIALIZATION

Support in the selection of the best technological solutions for large-scale production

Supplier networking

Technique for LOC prototyping

- Milling (PMMA, COC..)

- Soft lithography (PDMS)

- Photolithography e dry o wet etching (Silicon)

Detection options

- Optical (absorbance, fluorescence, chemiluminescence etc)

- Electrical (amperometry, voltammetry, impedance spectroscopy etc)

- Mechanical (quartz crystal microbalance, microcantilever etc)

Case study

Aim of the project

Design and realize a complex microfluidic path able to perform different biochemical protocols. The device was interfacedwith an automated manifold and a optical reader.

Challenges

- Non continuous flow

- Storage of reagents for 6 months without evaporation and migration along channels

- Design, material and process are choiced to achive a balance betwen the required function.

Results

DRIE (Deep Reactive Ion Etching) process have been calibrated especially for this application.

Case study

Aim of the project

Design and realize a complex microfluidic path able to perform different biochemical protocols. The device was interfacedwith an automated manifold and a optical reader.

Challenges

- Non continuous flow

- Storage of reagents for 6 months without evaporation and migration along channels

- Design, material and process are choiced to achive a balance betwen the required function.

Results

DRIE (Deep Reactive Ion Etching) process have been calibrated especially for this application.

REGISTERED OFFICE

Piazza Solferino, 20

10121 Torino

P.I. 11541890015