IOT Sensing system

Thanks to our competence in chemistry, material science and engineering, we are able to set up IOT sensing system for special applications in which conventional analyzers are not effective.

Our competence in chemistry, material science and engineering are made available to our costumers to set up IOT sensing systems in a strong synergic cooperation.

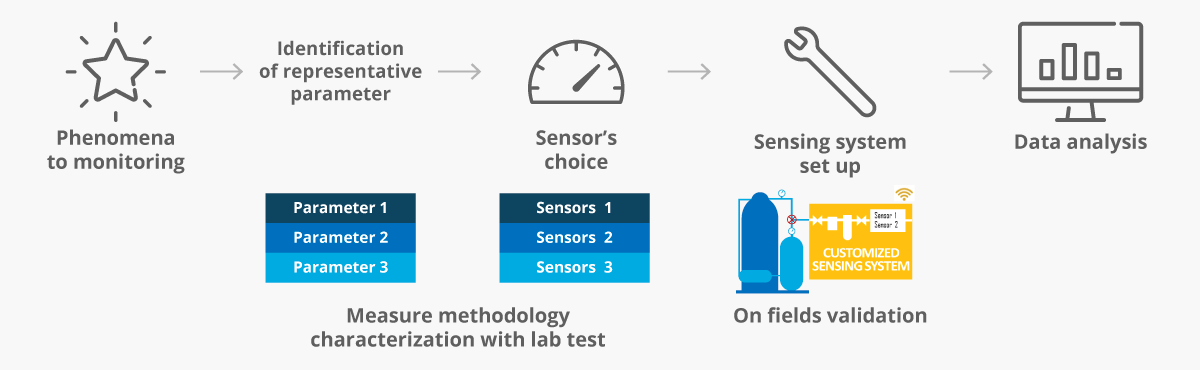

We define the monitoring strategy starting from the identification of the representative parameters. Probes are selected according to process constrains and are characterized with lab test using real samples. After the installation data are analyzed and compared with traditional test for the calibration. Data output is tunable on your need: from alert to connection with management platform.

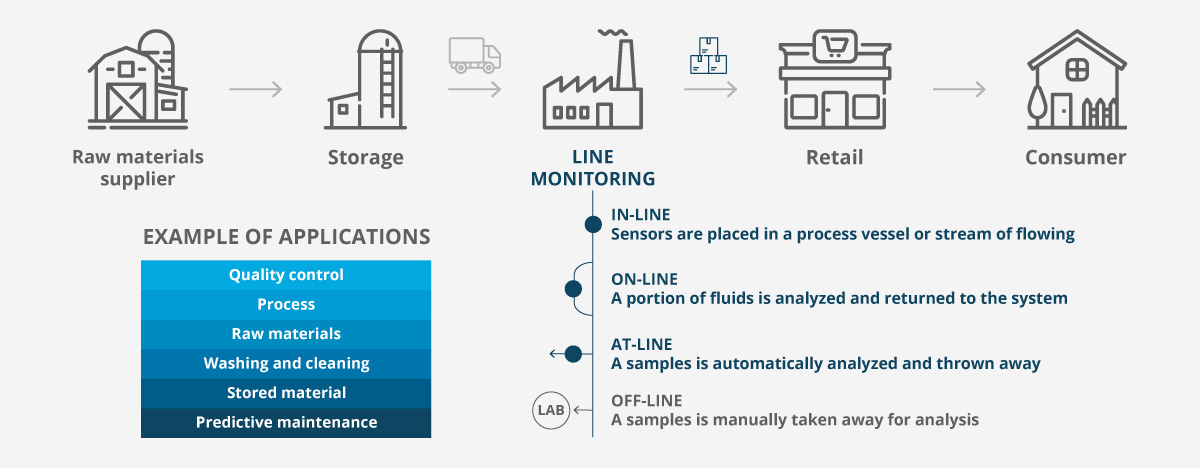

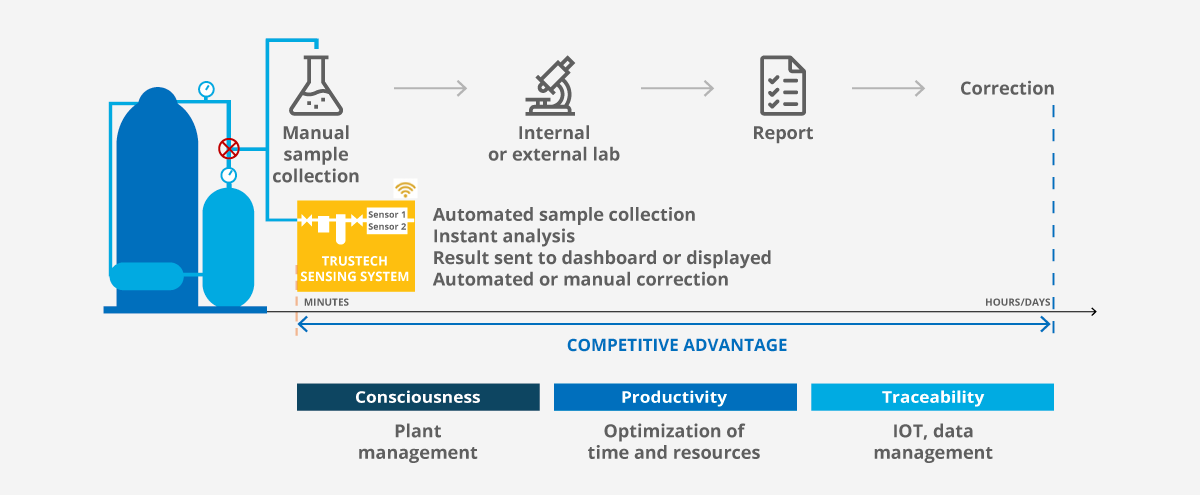

The advantages of line monitoring are the high sampling capacity and the real time feedback. Line measurements give an important support in the plant management. In addition to the laboratory analysis a further check step is possible to enhance quality and optimize costs of production.

Open loop control philosophy is based on conservative over estimation assumptions resulting in a waste of time and resources. With line measurement feedback you can take action when necessary.

Conductivity, pH, optical response, temperature and so on, are typically line measurable parameters. They indicate, directly or indirectly a deviation from the working conditions or the presence of contaminants.

Line monitoring is a useful tool to improve consciousness about the process condition, traceability and productivity.

Example of applications are:

- Quick test to support decision making (e.g. acceptance of raw materials)

- Every where continuous feedback is needed (e.g. to monitor phenomena that changing in time)

- Optimization of water and reagent consumption (e.g. washing solution in Clean-in-place CIP)

Case study

FOOD AND BEVERAGE

Problem

During production of cans, to facilitate sliding, a lubricating emulsion (ME) is applied to the cans. High ME concentration may cause problems in the subsequent painting. Operators periodically measured concentration by manual titration.

Approach

Common in-line parameter (as pH, conductivity..) were not effective in this application. We found an alternative chemical automated analyzes.

Delivery (6 Month)

We demonstrate the effectiveness of TOC (total organic carbon) analyzers for this application, and we provide a calibration by laboratory test. We verified the effectiveness of this solution contacting TOC analyzers providers.

Results

With an in line TOC analyzer the ME concentration is automatically monitored and corrected during process. No more painting issues caused by too high ME concentration.

AEROSPACE

Problem

Machined components must be cleaned of lubricating oils in special washing machines. Any residues may invalidate the subsequent tests. Process quality is affected by detergent concentration and water quality. Detergent concentration measured by the company laboratory, gave results in 24h. Washing and rinses tanks were replaced at pre-established intervals according to empirical observations.

Approach

We identified:

- chemical parameters influencing water quality

- detergent concentration measuring method

Delivery (6 Month)

We designed, realized and installed a demonstrator on the machine that automatically analyzes three different parameters at each process. Data have been sent to the company internal board. We follow up the Customer analyzing data and giving the right interpretation.

Results

Quality feedback at each process. Possibility to correct washing and rinses solutions when necessary. Data could be associated with the part numbers of the washed pieces.

MEDICAL

Problem

A Biological analysis require accurate temperature control. It was requested to create a device capable of measuring in real time the temperature simultaneously in rotating wells during the process.

Approach

We identify the constraints of the project: high mechanical solicitation of the electronics and assembly, small available space, high sensors resolution, usability.

Delivery

We design the electronic board specially for high speed rotating usage. We selected fast responsive electronic components withstanding radial acceleration and we developed a solutions for mounting the devices with appropriate seals and robustness.

- α prototype 4 months

- β prototype 2 months

- 4 unities of the final device 2 months

Results

Realization of a specific calibration tool for the diagnostic instruments.

REGISTERED OFFICE

Piazza Solferino, 20

10121 Torino

P.I. 09922510012