Case studies

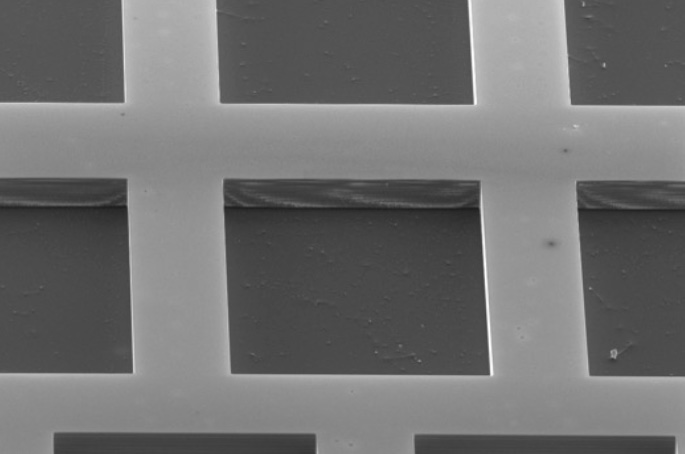

Microfabrications

Aim of the project

We demonstrate the feasibility of a deep through etch for the realization of a sensor for aerospace applications.

Challenges

- passing through etch on 525m silicon

- high verticality of the etched walls

Results

DRIE (Deep Reactive Ion Etching) process have been calibrated especially for this application.

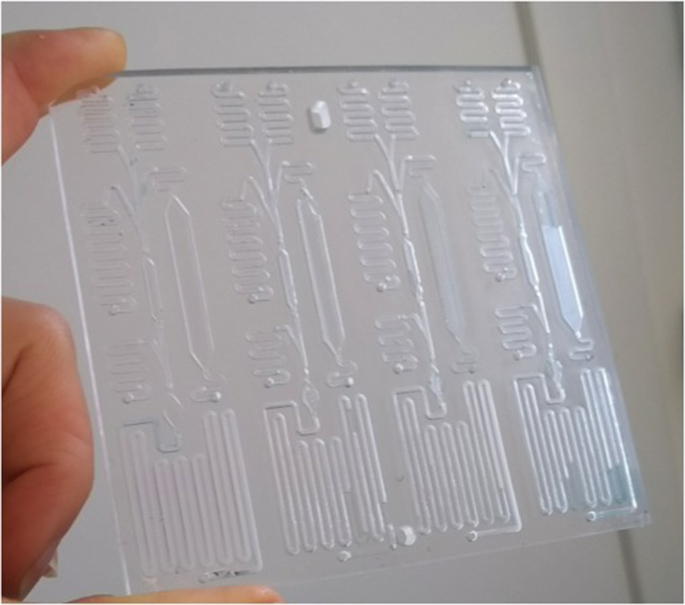

Microfluidics and LOC

Aim of the project

Design and realize a complex microfluidic path able to perform different biochemical protocols. The device was interfacedwith an automated manifold and a optical reader.

Challenges

- Non continuous flow

- Storage of reagents for 6 months without evaporation and migration along channels

- Design, material and process are choiced to achive a balance betwen the required function.

Results

DRIE (Deep Reactive Ion Etching) process have been calibrated especially for this application.

IOT sensing system

FOOD AND BEVERAGE

Problem

During production of cans, to facilitate sliding, a lubricating emulsion (ME) is applied to the cans. High ME concentration may cause problems in the subsequent painting. Operators periodically measured concentration by manual titration.

Approach

Common in-line parameter (as pH, conductivity..) were not effective in this application. We found an alternative chemical automated analyzes.

Delivery (6 Month)

We demonstrate the effectiveness of TOC (total organic carbon) analyzers for this application, and we provide a calibration by laboratory test. We verified the effectiveness of this solution contacting TOC analyzers providers.

Results

With an in line TOC analyzer the ME concentration is automatically monitored and corrected during process. No more painting issues caused by too high ME concentration.

AEROSPACE

Problem

Machined components must be cleaned of lubricating oils in special washing machines. Any residues may invalidate the subsequent tests. Process quality is affected by detergent concentration and water quality. Detergent concentration measured by the company laboratory, gave results in 24h. Washing and rinses tanks were replaced at pre-established intervals according to empirical observations.

Approach

We identified:

- chemical parameters influencing water quality

- detergent concentration measuring method

Delivery (6 Month)

We designed, realized and installed a demonstrator on the machine that automatically analyzes three different parameters at each process. Data have been sent to the company internal board. We follow up the Customer analyzing data and giving the right interpretation.

Results

Quality feedback at each process. Possibility to correct washing and rinses solutions when necessary. Data could be associated with the part numbers of the washed pieces.

MEDICAL

Problem

A Biological analysis require accurate temperature control. It was requested to create a device capable of measuring in real time the temperature simultaneously in rotating wells during the process.

Approach

We identify the constraints of the project: high mechanical solicitation of the electronics and assembly, small available space, high sensors resolution, usability.

Delivery

We design the electronic board specially for high speed rotating usage. We selected fast responsive electronic components withstanding radial acceleration and we developed a solutions for mounting the devices with appropriate seals and robustness.

- α prototype 4 months

- β prototype 2 months

- 4 unities of the final device 2 months

Results

Realization of a specific calibration tool for the diagnostic instruments.

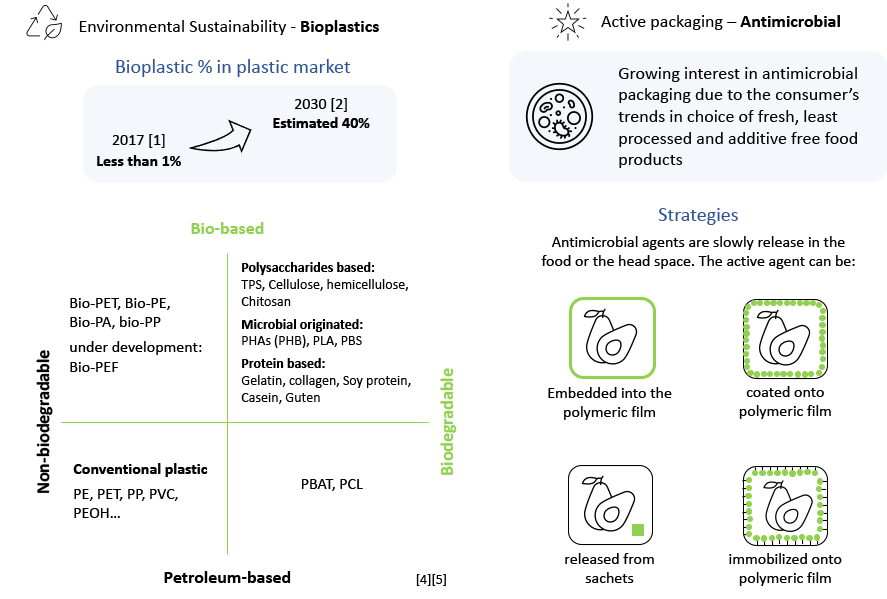

Technological assessments

Topic

Food packaging in the net 10 years

Aim od he project

provide guidelines for the definition of the R&D strategy of a food packaging company.

Approach

Firstly, we have described a whole scenario identifing the trends in food packaging, such as sustainability and safety. Then, we have tailored the research focusing on material and process of the customer interests.

The outcome is an overview of the research activities, currently underway, concerning food packaging technologies with different level of development.

Delivery

2 month

REGISTERED OFFICE

Piazza Solferino, 20

10121 Torino

P.I. 09922510012